Certified to Assure Quality

Every project adheres to our quality assurance program with detailed documentation to ensure quality and integrity— from raw materials, vendor selection and manufacturing processes through the shipping, handling and delivery of parts.

Our quality assurance system requires a thorough analysis of each process and component, and has played a large part in our continued success.

Our quality management system is structured to comply with the following quality system certifications:

AAR M-1003 QA: Specification for Quality Assurance

AAR M-1002 QA: Specifications for Tank Cars

Activity Code: B85 – Manufacturer of pressure-retaining tank components

Activity Code: C4 – Manufacturer of tank car service equipment

Facilities & Equipment

For today’s exacting manufacturing needs

We continually invest in our CNC machining centers and equipment to ensure we deliver the highest quality and precision for every part we manufacture.

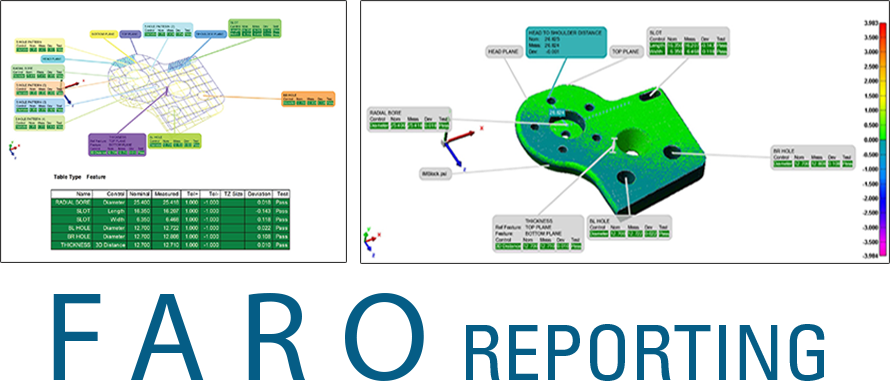

The FARO Arm

The FARO arm is used for complex parts with features that would be difficult or impossible to measure without it. The FARO arm uses both laser scanning and tactile probing to provide highly accurate measurements for critical components.

View FARO sample reporting below

Investing in our people

Training, Certification and Education

Our people are the heart of our operations. Hammond Machine Works employs craftsmen of the highest caliber and ensures their expertise with extensive training, certifications and continuing education.

Welders: Trained and certified to AWS and AAR standards.

Machinist Apprentice Program: Designed in cooperation with Purdue University, combines on-campus coursework and hands-on training in the machine shop at the Purdue Northwest School of Technology.